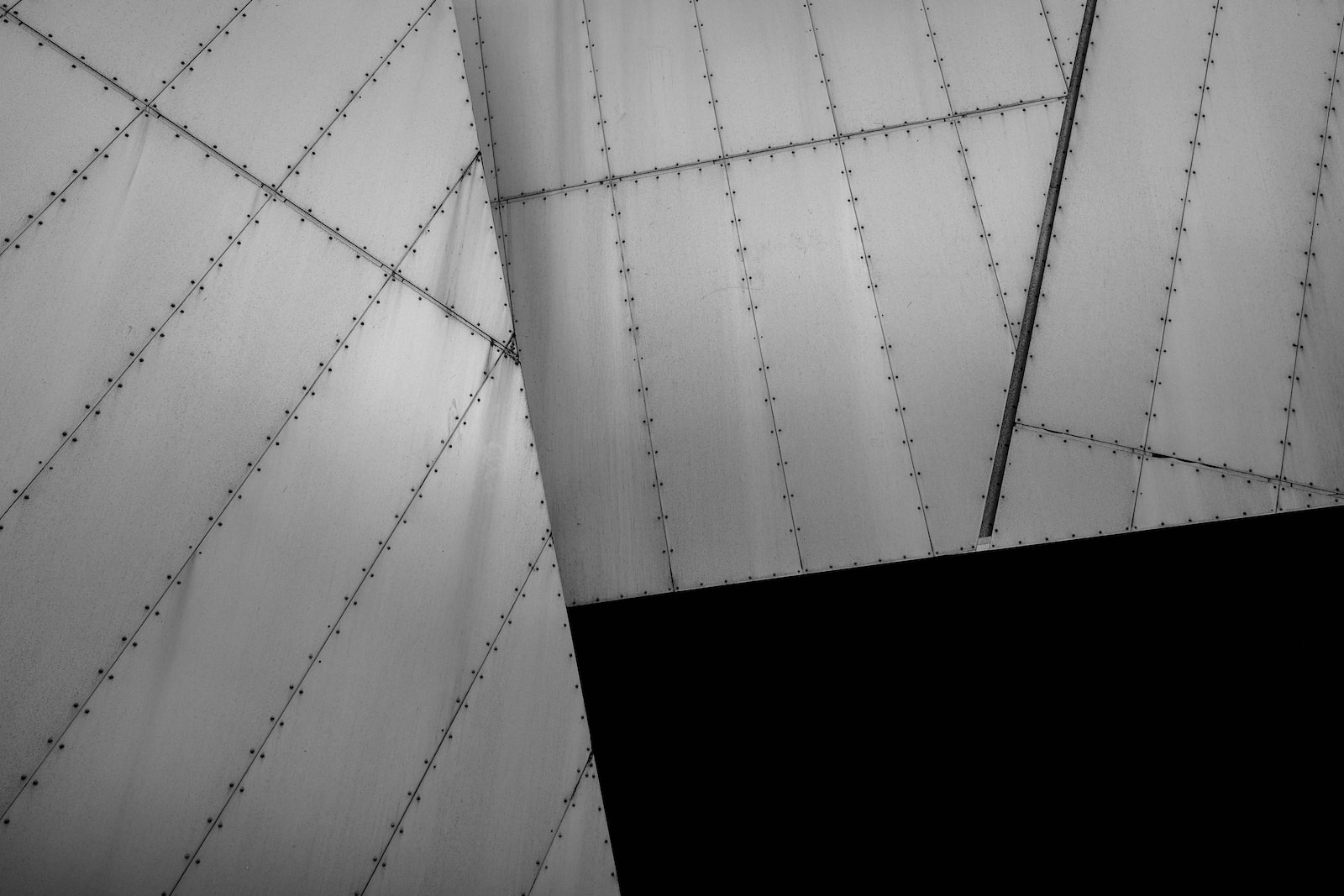

Sheet metal fabrication is the art of taking raw metal sheets and turning them into functional components. This is what drives things like cars, airplanes, medical tools and building structures. But have you ever wondered how sheet metal transforms into these components? We’ll take a look at how they’re made, from cutting and machining to bending, forming, welding, and assembly.

Cutting Techniques

If you want to turn a sheet of metal that doesn’t do much into a functional part, the process usually starts with cutting. Here are some techniques for cutting in sheet metal fabrication:

- Shearing – Uses blades to give straight-line cuts, which are good for making rectangular or square parts with clean edges.

- Laser Cutting – Laser beams do precise and clean cuts on metal sheets, making it an excellent choice for complex designs.

- Plasma Cutting – If you need high-velocity ionized gas to cut through metal sheets, then this is your go-to. It’s versatile and suitable for various thicknesses.

- Waterjet Cutting – For this method, high-pressure water streams is mixed with abrasive particles to precisely cut through sheets.

Machining Techniques

Intricate details and precise shapes need machining to be made. It involves

- CNC Machining: Machines use computer programming, so the machining process can be controlled with the help of software instead of physically doing it all yourself.

- Turning: This machine rotates the sheet of metal so that single-point cutting tools can slowly cut through it until you reach your desired shape, which is perfect for creating cylinders.

- Milling: A machine uses rotary cutters to basically remove material from your piece so you’re left with just what you need; after that, you can start shaping it into an intricate design.

Bending

So, you’ve made the metal sheet, right? And now you have to bend it to get the shape you want. There are a few common bending techniques you can use:

- V-Bending: This tool uses a punch and die to bend metal sheets into a V-shape. Perfect for producing sharp angles.

- Roll Bending: If you’re looking for curved components, roll bending has got you covered. Just slide your sheet through some rollers until you’re satisfied with the curve.

- Press Brake Bending: Although bends are created using this technique, they’re also always precise and consistent, thanks to the press brake tool.

Forming Techniques

These methods add depth and three-dimensionality to metal sheets. Such as:

- Deep Drawing: This turns a flat sheet of metal into something with depth, such as a cylinder or box. This is usually used for things like kitchen sinks and car parts.

- Stamping: By utilizing a die in this method, shapes can be pressed into metal sheets that are widely used in coins, nameplates, and appliances.

- Spinning: Perfect for producing cylindrical components; spinning takes a metal disk and rotates it against a form so it can create shapes like domes and cones.

Welding Techniques

- MIG Welding: Metal Inert Gas welding employs both wire electrode and shielding gas to create strong welds that are high-quality. It’s great for many different applications due to its versatility.

- TIG Welding: Precision at its finest, Tungsten Inert Gas welding often works with delicate, thin metal sheets while providing exceptional control over the process.

- Spot Welding: The last on the list uses electrodes to provide heat and pressure directly onto specific points on the metal sheet to join them together quickly and efficiently. Great for producing automotive bodies.

Assembly Techniques: Bringing It All Together

The process of creating a final sheet metal product usually involves putting multiple parts together. Here are three ways that it can be done:

- Riveting: This technique is where you pass a rivet through pre-drilled holes and deform it to secure the parts together.

- Adhesive Bonding: A special adhesive is used to join metal parts. It’s most useful in situations where welding won’t work or when you want a clean appearance.

- Fasteners: Bolts, screws, and nuts are used to firmly attach metal parts so that they can be taken apart later if needed

So that’s it. These are the techniques used in designing, cutting, rolling, bending, joining and generally fabricating sheet metal. For more information on fabrication or if you want to purchase fabricated products, visit VASUCC SHEET METAL today.