Quality assurance is an essential element to ensuring the performance and reliability of any product. When it comes to panel connectors, the same holds true. These connectors are used in a wide range of applications, such as industrial machinery, electronic devices, and communication systems. In order to ensure the performance of these connectors, quality assurance measures must be taken.

Panel connectors are a typical component found in a range of sectors, including aerospace and electronics. Panel connector quality assurance procedures are a significant step in the production process and should be treated carefully. The use of an ohmmeter to test the connections for good electrical contact, visual examination with the help of AI Inference cameras to check for structural integrity, and a thorough record-keeping system to monitor each connector’s performance are just a few examples of the quality assurance techniques that should be used.

When choosing materials for panels, producers should take into account aspects like current rating, voltage rating, and temperature rating. Top panel connectors must also be built from high-quality materials that can endure the climatic conditions in which they will be utilized, according to manufacturers.

When choosing materials for panels, producers should take into account aspects like current rating, voltage rating, and temperature rating.

Perform Environmental Tests for Panel Connectors

In any electronic system, the panel connectors play a pivotal role in its functioning. They serve as the interface link between the various components of the electric system and the external environment. As such, they are prone to many environmental stresses, such as extreme temperatures, high vibrations, and dust and corrosion. To ensure their optimal performance, the panel connectors must be tested against these environmental conditions.

When conducting tests on panel connectors, it is important to consider their environmental impact. Environmental testing of the connectors helps ensure their compatibility with their intended environment. This includes testing for temperature, humidity, and other environmental conditions that could affect the performance of the connectors. In addition, the connectors should be tested for corrosion resistance and vibration to ensure the long-term integrity of the connections. Testing should also be conducted to ensure the connectors are properly sealed and that they meet any applicable safety requirements. Environmental testing of panel connectors is essential to ensure reliable performance and safe operation.

Verify Electrical Performance

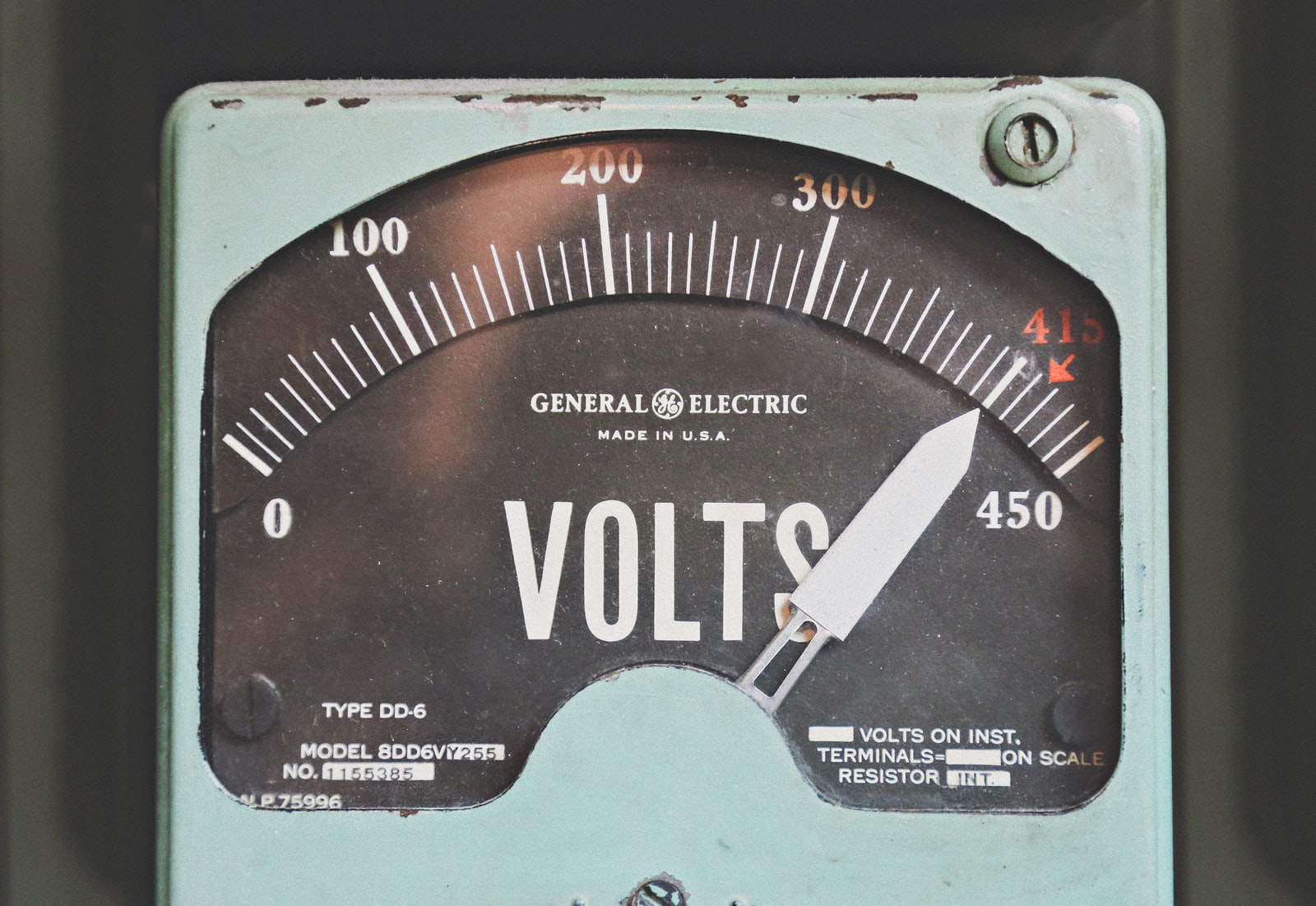

Verifying electrical performance is an important part of ensuring reliable and safe operation of electrical equipment. It is essential to regularly test and inspect electrical systems to ensure they are performing as expected and working safely. Depending on the specific equipment, this can involve a variety of testing methods, such as voltage drop and insulation testing.

Verifying the electrical system’s performance is crucial to guaranteeing that all electrical performance is accurate. Numerous tests, including load testing, voltage testing, and continuity testing, can be used to accomplish this. Each kind of test is intended to deliver particular details about the system’s electrical performance. The electrical system’s current and voltage will be measured during a load test to make sure they fall within allowable bounds. By measuring the output voltage level of the system, voltage testing can be used to confirm that the voltage is at the proper level. Finally, continuity checks will look for any electrical circuit breakdowns that might be the source of unforeseen performance problems.