Aluminum Extrusion is a critical player in many industries and offers versatile and lightweight solutions for numerous applications. In the ever-changing technology landscape, the process of aluminum extrusion has been significantly improved, leading to better efficiency, sustainability, and overall quality.

By the way, we keep track of trends in aluminum extrusion, trying to see what new technologies are emerging there. With that said, four of those latest technologies contribute to increased productivity and higher product value.

Advanced Aluminum Extrusion Machines

Over recent years, there have been several advancements in technology with respect to aluminum extrusion machines that were previously limited by their energy consumption rates. This equipment increases productivity and attributes low energy usage and quick heating speeds. Designed with fewer oil leakages, this limits customer loss, promoting sustainable manufacturing practices.

Integrated Aluminum Alloy Profile Support Systems

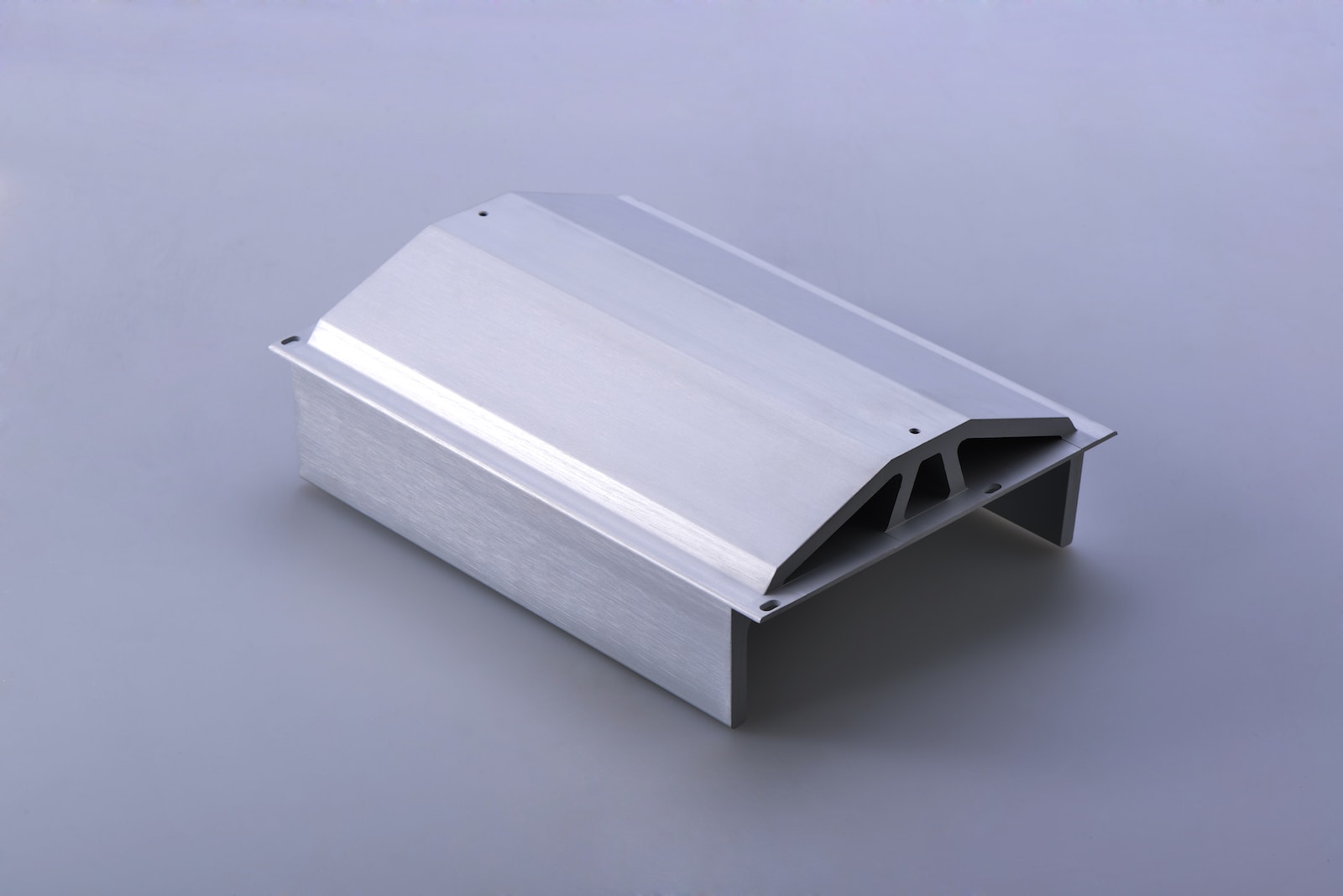

The aluminum industry has evolved, leading to increased demand for high-quality aluminum profiles in emerging sectors. Integrated aluminum alloy profile support systems have been developed in response to this demand.

These holistic systems merge the extrusion machine with other machines that help handle the metals, aging furnaces, and surface treatment machines as one unit. As a result, these processes enhance production efficiency, increasing productivity and better-quality products.

Automation and Intelligent Production

Aluminum extrusion is one of the many manufacturing processes increasingly relying on automation. Modern technological developments enable aluminum extrusion machines to be automated and have the intelligence required for production. This reduces the number of operators and maintenance employees necessary, thus making the process more streamlined and efficient extrusion.

Intelligent systems monitor and control different parameters, ensuring accurate results after each extrusion. Rapid changes in production parameters are made possible through a quick barrel swap mechanism, enabling it to align with these advancements, which can handle different specifications easily.

Personalized Customization for Specific Accuracy Requirements

Modern technology makes it easier to recognize the differentiation of demand from different industries, making the personalization of extrusion machines easy regarding precision requirements. The machine features can, therefore, be customized in whatever the manufacturer wants and thus guarantee that shaping will be accurate, control limits will be achieved, and delicate appearance surfaces will be obtained. This makes aluminum extrusion a very versatile field by supporting intricate designs.

An ongoing, ever-growing technological trend in aluminum extrusion leads to its efficiency, quality, and sustainability. The latest/advanced machines used in aluminum extrusion have led to decreased energy consumption and a consequent increase in overall productivity. With the integration of integrated systems, processing in production is becoming better and more intensive for the manufacture of top-quality aluminum profiles.

Excessive automation and smart manufacturing give more efficiency during extrusions. Different areas with applications require specific limitations from manufacturers.

This is why we are dedicated to being a leading innovative pioneer in these technologies. We keep innovating and ensuring that our customers can access the new technologies available in aluminum extrusion. You can browse our latest extruders, including precision, speed, and efficiency. These advances will help you optimize your extrusion processes, improving product outcomes and keeping you ahead in a fast-changing marketplace.